Termination Kit

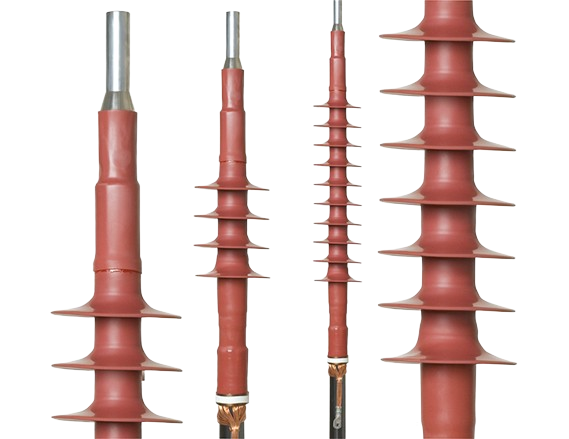

Heat Shrink High Voltage Terminations

HV Heat Shrink Termination. Heat shrink high voltage terminations upto 72 kV are in service for over 40 years. They are suitable for installation in all climates, environments and polluted areas. Heat shrink high voltage termination comply to IEC 60840.

Parameter

- Heat-shrinkable stress control sleeves

- Non-tracking, heat-shrinkable outer insulation

- Water and corrosion-resistant

- Different creepage distances available

- Suitable for compression and mechanical lugs

- No oil or compound filling

- Tested under International standards

Technical Information

|

Sr no. |

Particulars |

Specifications |

|---|---|---|

|

1 |

Applicable Standards |

IEC 60840 |

|

3 |

Highest System Voltage |

72.5kV |

|

3 |

Nominal System Voltage |

66kV Phase to Phase |

Heat Shrink Medium Voltage Terminations

Medium Voltage Heat Shrink Terminations-Conventional and next generation

- Conventional Terminations - Universal termination based on impedance (resistant) based stress control system upto 36 kV

- Immediate energization after completion of termination

- Conforms to various national and international standards like CENELEC HD.629.1.S2:2006, IEC 60502-4, IEEE 48 and IS 13573-2

Parameter

- Unlimited shelf life for heat shrink components

- Suitable for wide range of connectors

- Immediate energization

- Pre-Engineered Kit

- Tested as per National & International Standards

Technical Information

|

Sr no. |

Particulars |

7.2 KV |

12 KV |

24KV |

36KV |

|---|---|---|---|---|---|

|

1 |

Applicable Standards |

60502-4, CENELEC HD 629.1, IS 13573-2 |

|||

|

2 |

Rated Voltage of cable accessories |

3.8/6.6 (7.2) |

6.35/11 (12) |

12.7/22 (24) |

19/33 (36) |

|

3 |

Accessories |

Heat Shrink type |

|||

|

4 |

AC Voltage test Dry for 5 minutes Wet for 1 minute |

17.1 kV 15.2 kV |

28.5 kV 25.4 kV |

57.1 kV 50.8 kV |

85.5 kV 76 kV |

|

5 |

DC Voltage test for 15 min |

15.2 kV |

25.4 kV |

50.8 kV |

76 kV |

Jointing Kit

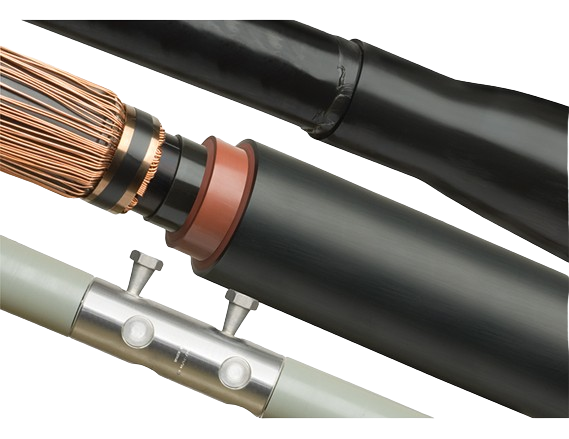

Heat Shrink Medium Voltage Joints

Medium Voltage Heat Shrink Joints-Conventional and next generation. Raychem developed highly specialized polymers for heat shrink joints suitable for plastic and paper cables upto 36 kV. For transition joints, a special oil barrier tubing is used to transform draining oil (MI) and non-draining oil (MIND) paper insulated cable into quasi-polymeric insulated cable with a radial field.

The conventional design developed in 1980 was based on multiple layer tubing concept providing insulation and stress functions. The latest developed heat shrink joint is a single tubing (triple layer co-extruded) of adequate thickness which provides insulation for a particular voltage range.

- Conventional Joints - Multi-layered heat-shrinkable tubing incorporating precisely engineered impedance stress control. EPKJ universal joints are suitable for a wide range of connectors and cable sizes with no limitations on shelf life

- Joints are suitable for all types of cables having different screening and armour designs

- Immediate energization after completion of joints

Parameter

- Unlimited shelf life for heat shrink components

- Suitable for wide range of connectors

- Immediate energization

- Pre-Engineered Kit

- Tested as per National & International Standards

Technical Information

|

Sr no. |

Particulars |

7.2 KV |

12 KV |

24KV |

36KV |

|---|---|---|---|---|---|

|

1 |

Applicable Standards |

IEC 60502-4, CENELEC HD 629.1, IS 13573-2 |

|||

|

2 |

Rated Voltage of cable accessories |

3.8/6.6 (7.2) |

6.35/11 (12) |

12.7/22 (24) |

19/33 (36) |

|

3 |

Accessories |

Heat Shrink type |

|||

|

4 |

AC Voltage test Dry for 5 minutes Wet for 1 minute |

17.1 kV 15.2 kV |

28.5 kV 25.4 kV |

57.1 kV 50.8 kV |

85.5 kV 76 kV |

|

5 |

DC Voltage test for 15 min |

15.2 kV |

25.4 kV |

50.8 kV |

76 kV |

Heat Shrink High Voltage Joints

HV Heat Shrink Joint. Polymeric insulated cables of various designs can be adapted with respect to shielding and metal sheath. Raychem heat shrink accessories have been used by utilities and industrial companies around the world for over 40 years. The ongoing field experience makes Raychem a leader in materials science and technology for high voltage applications. The materials used in TE Connectivity Raychem cable accessories are extensively optimized with respect to product design, function, manufacturing and expected service environment.

- Compact and modular design

- Quick and easy to install

- No special or expensive tools required

Parameter

- Heat-shrinkable stress control sleeves

- Torque-controlled connector

- Water and corrosion-resistant

- Joint fits on all polymeric cable constructions

- Proven shield continuity concept

Technical Information

|

Sr no. |

Particulars |

Specifications |

|---|---|---|

|

1 |

Applicable Standards |

IEC 60840 |

|

3 |

Highest System Voltage |

72.5kV |

|

3 |

Nominal System Voltage |

66kV Phase to Phase |